top 7 applications! look here for high viscosity dimethicone fluids!

linear dimethyl silicone oil with si-o-si as the main chain and methyl groups attached to the silicon atoms. due to the small intermolecular forces, the molecule has a helical structure with the methyl groups arranged outward and free to rotate, and the structural formula is as follows:

thus, it has a series of characteristics, such as colorless and transparent, wide range of viscosity (from 0.65 to 1,000,000mm2/s), temperature viscosity coefficient is small, expansion coefficient is large, low vapor pressure, high flash point, high and low temperature, weathering, irradiation, low surface tension, high compression rate, anti-oxygen plasma, high insulator, shear resistance, film-forming properties, water-repellent, antifoaming, demolding, high gloss, inert to the material, chemically inert, corrosion-free, and have a chemical inertia. inert, non-corrosive and physiologically inert, it is these properties that determine its wide range of uses.

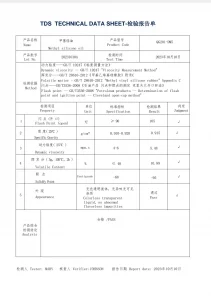

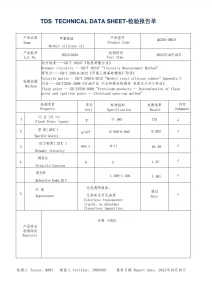

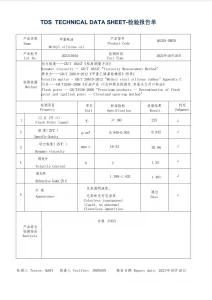

generally according to the dimethyl silicone oil viscosity range, can be divided into three categories of specifications:

low viscosity silicone oil 0.65~50mm2/s;

medium viscosity silicone oil 50~1000mm2/s;

high viscosity silicone oil 1000~1000000mm2/s.

high viscosity dimethyl silicone oil is synthesized by high quality new material, stable quality, in line with eu rohs standards. conventional high viscosity has 12500 viscosity, 60,000 viscosity, 300,000 viscosity, 500,000 viscosity, other high viscosity can be customized.

main applications

daily chemical industry

it can be used in cosmetic formulations such as skin cream, shower gel, shampoo, etc. it has excellent soft effect and silky feel, and has the functions of moisturizing and protecting skin.

electromechanical industry

it can be widely used in electric motors, electrical appliances, electronic instruments as temperature resistance, arc corona resistance, corrosion resistance, moisture, dust insulation medium, and is also used as impregnating agent for transformers, capacitors, and scanning transformers of tv sets. in a variety of precision machinery, instruments and meters, used as a liquid shockproof, damping materials.201 methyl silicone oil anti-vibration performance is affected by the temperature is small, and is used for strong mechanical vibration and ambient temperature changes in the occasion, the use of instruments such as: aircraft, automobile instrumentation.

antifoam agent

due to the dimethyl silicone oil surface tension is small, and insoluble in water, animal and vegetable oils and high boiling point mineral oil, chemical stability, and non-toxic, as an antifoaming agent has been widely used in petroleum, chemical, medical, pharmaceutical, food processing, textile, printing and dyeing, paper and other industries, as long as the addition of 10-100ppm of silicone oil has a good antifoaming agent role.

as mold release agent

it is non-adhesive to rubber, plastic, metal, etc., and is used as a mold release agent for all kinds of rubber and plastic products, and for precision casting. it is not only convenient for mold release agent, but also makes the surface of products clean, smooth and clear texture.

insulation, dustproof, moldproof coating

in the glass, ceramic surface dip-coated layer of 201 methyl silicone oil, and heat treatment at 250-300 ℃, can form a layer of semi-permanent waterproof, mildew and insulation of the film. with the treatment of insulating devices, can improve the insulating properties of the device: with the treatment of optical instruments, can prevent moldy lenses, prisms; with the treatment of medicine bottles, can prolong the preservation period of the drug, and does not make the preparation due to the loss of sticking to the wall; with the treatment of the surface of the movie film can play a lubricating role in reducing the friction, extending the life of the film.

lubricant

it is used as lubricant for rubber, plastic bearings and gears. it can also be used as a lubricant for steel-to-steel rolling friction at high temperatures, or for friction between steel and other metals.

additive

it can be used as additives for many materials, such as as a brightener for paint, add a small amount of silicone oil to the paint, can make the paint does not float package, do not wrinkle to improve the brightness of the film, add a small amount of silicone oil to the ink, can improve the quality of printing, add a small amount of silicone oil to the polishing oil (such as automotive varnish oil), can increase the brightness, protection of the paint film, and has excellent waterproofing effect.

application of dimethyl silicone oil

01

role in rubber, plastic, metal mold release

due to the non-stick property of dimethyl silicone oil and rubber, plastic, metal, etc., it can be used for the mold release of polyurethane microporous elastomer molding products, and also can be used for the mold release of crusted polyurethane molding products, rubber products, abs molding products and so on. the main advantages of this release agent are small release force, no pollution, convenient transportation, and clean, smooth and clear texture of the product surface. with the rapid development of polyurethane industry, the market of silicone oil mold release agent is expanding.

02

silicone oil in the textile industry

silicone oil in the textile and garment industry can be used as fabric softener, lubricant, waterproofing agent, finishing agent and so on. in order to meet the high-end demand for textiles, chemical manufacturers are also constantly developing with a variety of functional additives such as waterproofing agents, flame retardants, antistatic agents, color-fixing agents, such as the use of the same bath, feel good silicone oil. in addition, in order to improve the performance of fabrics, there are silicone products that can be used in the same bath with dyeing, silicone oils for cotton with a cool feeling, and silicone oils that can improve the performance of fabrics.

in addition to the functionalization of textiles as additives, silicone products will also be used in other areas of textiles. in addition to the textile as an additive to achieve the functionalization of textiles, silicone products will also be applied to other areas of textiles, such as silicone and polyurethane combination to form the coating of fabrics; silicone and acrylic polymerization to form the printing of fabrics; silicone and fluorine combination of the formation of fabric surfaces of the waterproof coating and so on.

03

application of silicone oil defoamer

silicone oil antifoam agent generally has high defoaming efficiency, commonly used silicone antifoam agent are silicone oil as the basic component, with appropriate solvents, emulsifiers or inorganic fillers formulated. organo-silicon defoamer is low toxicity, antioxidant, strong bubble breaking ability defoamer, so it is widely used in printing and dyeing industry and wastewater defoaming industry.

04

application of silicone oil in cosmetics

polydimethylsiloxane can be used as silicone surfactant, which is a colorless, odorless, non-irritating, non-volatile thin to viscous fluid. has the following good characteristics: ① good lubricating properties, after coating the skin can form a layer of uniform waterproof protective film, but there is no viscous and greasy feeling; ② good gloss. good performance of anti-ultraviolet radiation. it will not oxidize and deteriorate under ultraviolet rays and cause skin irritation. ③ good anti-static properties, tests show that the skin containing polysiloxane skin cream wiped with all the elimination of static electricity, and there is a significant dust effect of good breathability, even if the formation of silicone film on the skin does not affect the sweat discharged. ④ it has a slow-release role in the fragrance and flavors, and thus a longer period of preservation of the fragrance of high stability, chemical inertia, other components of cosmetics, especially the active ingredient does not have any adverse effects on the matching of good.

05

application of silicone oil in electromechanical industry

dimethyl silicone oil is widely used in electric motors, electrical appliances, electronic instruments as temperature resistance, arc corona resistance, corrosion resistance, moisture, dust insulation medium, is also used as a transformer, capacitors, tv scanner transformer impregnants. in a variety of precision machinery, instruments and meters, used as liquid shockproof, damping materials. dimethyl silicone oil shock absorbing performance is affected by the temperature is small, mostly used for strong mechanical vibration and environmental temperature changes in the occasion, the use of instruments such as: aircraft, automobile instruments. used for anti-vibration, damping, stabilization of instrument readings, but also as a liquid spring, and in the aircraft landing device.

06

application in paint

silicone oil surface tension is very small, and has a unique interfacial properties, in coatings and inks, add a small amount of low-viscosity dimethyl silicone oil, both can effectively reduce its surface tension, improve the spreadability and expandability, to obtain no orange peel, the appearance of a uniform coating. compared with traditional coatings, polysiloxane coatings have many excellent properties, so they occupy a very important position in the coating industry, especially in the application of functional coatings will be more and more. polysiloxane coatings have the following characteristics: ① excellent film light retention and color retention, high gloss, decorative, corrosion resistance, chemical resistance, and good physical and mechanical properties of the film, film drying speed, high construction efficiency, and stain resistance, easy to clean; ② construction does not need to apply intermediate coatings to reduce the number of coating channels, ③ high solid coatings, low voc content, does not contain isocyanate, small odor, safe, healthy and environmentally friendly features. it has the characteristics of safety, health and environmental protection. therefore, polysiloxane coatings are used in architectural coatings.

07

application in medicine

because polysiloxane is non-toxic, odorless, biocompatible, non-skin sensitizing, physiologically inert, resistant to high and low temperatures, non-combustible, breathable, unique solution permeability and physical and chemical properties of the stability of the characteristics of a wide range of applications in the field of medicine. dimethyl silicone oil cream can prevent the skin from acid, alkali, salt and various detergents. silicone oil can be made for medical defoamer, skin protection agent, can be used to formulate the treatment of various burns and skin diseases of topical medicine, can also be made with anti-caries, anti-allergic double effect of silicone toothpaste; in addition, polysiloxane in the pharmaceutical field also has a wide range of applications.

08

other applications

for insulation, dust, mold coating: in the glass, ceramic surface dip-coating a layer of dimethyl silicone oil, and heat treatment at 250-300 ℃, can form a layer of semi-permanent waterproof, mold and insulating film. with the treatment of insulating devices, can improve the insulating properties of the device: with the treatment of optical instruments, can prevent moldy lenses, prisms; with the treatment of medicine bottles, can prolong the preservation period of the drug, and does not make the preparation due to the loss of sticking to the wall; with the treatment of the surface of the movie film can play a lubricating role in reducing the friction and extend the life of the film.

we establish a good relationship with customers, regular technical exchanges, cooperation in the development of new projects, some products provide customized services!

![DMAEE CAS1704-62-7 2-[2-(Dimethylamino)ethoxy]ethanol](http://dmaee.cn/wp-content/uploads/2022/11/cropped-logo1.jpg)